|

SARE FRP Grating Company

|

High quality FRP Gratings

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

FRP Gratings with Light Weight but High Strength

FRP Gratings with Light Weight but High Strength

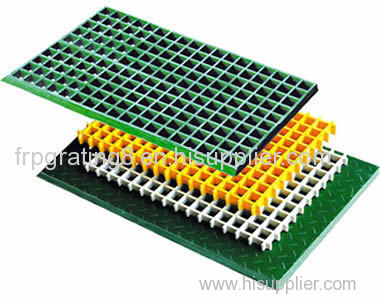

SARE Company's FRP/GRP gratings (Fiberglass Reinforced Plastic Gratings) are interwoven from glass fibers, cast resin and then molded into FRP grating plates with regularly distributed rectangle or square holes, and they have perfect bi-directional mechanical properties. FRP gratings can be widely used for the working platforms, equipment platforms, drilling platforms andwalkways of petroleum, chemical electronics, electricity, paper, printing and dyeing, electroplating, ocean exploration, sewage treatment and so on. They are the ideal choice for corrosive environments, but also can be applied to civil construction facilities.

Square-hole FRP gratings have stable structure for wide applications.

FRP gratings have various colors and different surface types according to customers' request.

Three kinds of manufacturing techniques:

Reciprocating filament winding process.

Continuous filament winding process.

Centrifugal pouring process.

- Resin typeResin baseDescriptionCorrosion resistanceColorsUsage temperatureType-V-1Type-V-2Type-V-3Type-I-1Type-I-2Type-O-1Type-O-2

Type-V-1

This resin is highly corrosion resistant, no matter in acidic or caustic environments, and it is especially solvent resistant. Its flame spread rating is 25 or less according to ASTM E-84 tunnel test.Type-V-2 & Type-V-3

This high corrosion resistant resin is the ideal choice for high flammability conditions, and its flame spread rating is 10 or less according to ASTM E-84 tunnel test.Type-I-1

This resin is widely used for moderately corrosive environments like industrial and chemical operating applications. Its flame spread rating is 25 or less according to ASTM E-84 tunnel test.Type-I-2

This resin system can be used in meat, food, bottling and brewing processing applications. The flame spread rating is 30 or less according to ASTM E-84 tunnel test.Type-O-1

This resin system is designed to meet mildly corrosive conditions, and its flame spread rating is 25 or less according to ASTM E-84 tunnel test.Type-O-2

This resin system is designed to meet mildly corrosive conditions, but it is not fire retardant.Naturally concave surface.

Polished smooth surface.

Sanding surface.

Gritted top covered surface.

Pattern covered surface.

Molded FRP gratings

Pultruded FRP gratings

Pultruded FRP grating mainly have three types: I-shape bars, T-shape bars and high-load bars.Corrosion resistant

Resisting to acid, alkali, organic solvents, salts and many other gases and liquid media, FRP gratings have incomparable superiority in the field of preservation. According to the practical application requirements, orthophthalic, isophthalic and vinyl resins can be chosen as matrix material FRP gratings are widely used in all the aspects of chemical preservation, and they are replacing carbon steel, stainless steel, wood and non-ferrous metals.Lightweight & high strength

Because FRP grating is a composite of resins and fiber glasses, its density is less than 2 kg/dm3, which is 1/4 of the steel density and 2/3 of aluminum density. FRP grating's strength is ten times of RPVC, and its absolute strength level is higher than aluminum and ordinary steel. Its lightweight can greatly reduce the basic support, so as to reduce the material costs of the project. FRP gratings are easy to cut and install, no flame and large lifting equipment is needed, only need a small number of manual and electric tools, so as to reduce the installation costs.Ergonomic

Workers would get tired after a long time working on solid concrete or steel platforms, but FRP gratings can ease the strain their backs, feet and legs, so as to increase their comfort and work efficiency.Good thermal performance

FRP grating has low thermal conductivity - 1.25 - 1.67kj/(m.h.k) at room temperature, which is only 1/100 - 1/1000 of metals, therefore it is an excellent insulating material. In the case of instantaneous ultra-high temperature, FRP gratings are ideal for thermal protection and ablation resistance.Inflaming retarding

The flame propagation rate of ordinary flame retardant grating does not exceed 25, and the flame propagation rate of superb flame retardant vinyl grating does not exceed 10. The oxygen index is not less than 28.Security with good electrical properties

FRP grating has excellent electrical insulation properties as an insulator, and it can still protect good dielectric properties under high-frequency. Due to the good microwave permeability, FRP gratings have been widely used in radar and radome. Due to the no breakdown under 10KV voltage and no electromagnetic, FRP gratings can be used on equipment sensitive to magnetism. And the special structure of FRP grating has the features of anti-slip and anti-fatigue.Uniform color

The color can be arbitrarily chosen, according to the request of customers, improving the workplace environment.Outstanding designability

A variety of structured FRP gratings can be designed to meet the customers' requirements, letting the products have good integrity. And the materials can fully satisfy the product performance, such as corrosion resistant, instantaneous high temperature resistant, high tensile strength and good dielectric property.Good manufacturability

One-step molding process, prominent economic effect.Have good overall economic efficiency

Anti-aging

More than twenty years of service lives.Water treatment: maintenance walkway, sewer covers, large containers, clean device, trash rack, launder, biochemical water pool rack, hopper window, stair, cooling tower station pavement.

Chemical industries: stair tread plate, platform, fence, double floor, trench cover, filter shed.

Oil industries: offshore oil platforms.

Textile industries: replacement of steel grating and wood platform, covering the concrete platform, the ground around bleaching vat and valve.

Power station: the cover of chemical waste water trench and pool.

Metal surface treatment: pickling place, replacing the wood floor around the machine and highly corrosive container, plating line walkway, double floor.

Marine food processing industries: for the creamy surface on the ship.

Transportation: platform, ship decks, walkway, military minesweepers, stair tread plate.

Beverage industries: stair tread plate, replace expensive stainless steel, load floor.

Pulp and paper: stair tread plate, floor, walkway and humid place.

Electronics industries: trench cover, pickling workshop, anti-static and high cleanliness workshop.

Meat-processing industries: readily corrodible floor, slippery floor and stair tread.

Carwash room / Automobile beauty shop: the drainage board, parking place, trench cover of wash room.

Others: corrosion resistant shelves, decoration, square fountain, scaffolding, civil construction facilities, aquaculture fence and double floor.

And nowadays, manufacturers who use reciprocating filament winding process are much more than the other two production technologies manufacturers, one of the reasons is that the FRP gratings made by the reciprocating filament winding process have a wider range of applications and better applicability.

Resin system:

| Vinyl ester | Superior corrosion resistant and retardant. | Excellent | Dark green, orange | -50℃ - 110℃ |

| Vinyl ester | Superior corrosion resistant and enhanced retardant. | Excellent | ||

| Vinyl ester | Industrial grade corrosion resistant and fire retardant. | Very good | ||

| Isophthalic polyester | Industrial grade corrosion resistant and extra fire retardant. | Very good | Green, yellow, light grey | -50℃ - 90℃ |

| Isophthalic polyester | Food grade corrosion resistant and fire retardant. | Very good | ||

| Orthophthalic polyester | Moderate corrosion resistant and fire retardant. | Moderate | Green, light grey | -50℃ - 60℃ |

| Orthophthalic polyester | Moderate corrosion resistant. | Moderate |

Surface types:

Common surface types:

FRP gratings naturally have concave surfaces, so as to anti skid and ensure safety.

FRP gratings with polished smooth surfaces have beautiful appearances and stable structures.

FRP gratings with sanding surfaces have excellent anti-skid characteristic to ensure safety.

The sanding surfaces are non-slid to ensure the safety of people on them.

Covered surface types:

The gritted top covered surface can not only anti skid but also enhance the strength.

The gritted top covered surfaces can further enhance the stability and safety of pultruded FRP gratings.

The diamond shape surface makes the FRP gratings anti-skid and safe.

The five-bar shape surface of FRP gratings can ensure the people' safety wherever they are used.

Classifications:

FRP gratings are mainly divided into two kinds - molded FRP gratings and pultruded FRP gratings.

FRP gratings usually have square holes to ensure stable structures.

The size of FRP grating panels are flexible, and they can be cut into any size and shapes as you like.

This kind of pultruded FRP gratings have T-shape bars and small open areas.

Pultruded FRP gratings with I-shape bars are the most common used type.

Pultruded FRP gratings with high load bars are mainly used for heavy duty applications.

The FRP gratings around tree roots can protect the ground from being polluted by rubbish.

FRP gratings are anti-rust and corrosion resistant, so they can be used over water for a long time.

Applications:

FRP gratings are high corrosion resistant enough to deal with waste liquid.

FRP gratings spread on the walkway can help anti slip, so as to ensure people's safety.